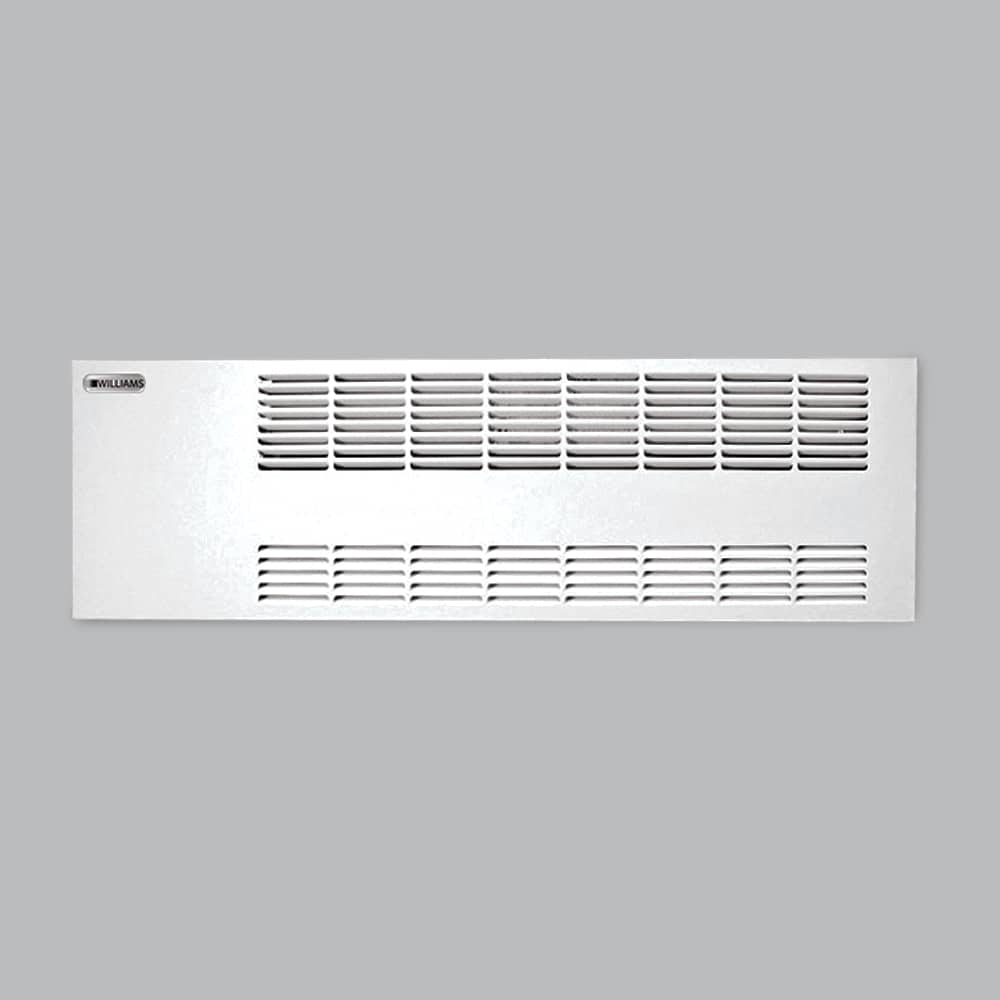

Vertical Modular / LV-M

Williams

Vertical Modular / LV-M

Product Details

Our Vertical Modular (LV-M) is our standard vertical slope top model with a flat top cabinet. A removable, single piece front panel provides complete access to the unit for servicing the motor, coil, valve package, drain pan, filter and all other components. The cabinet includes top discharge and front-return grilles.

CUSTOMIZATIONS

CONSTRUCTION

All unit chassis shall be fabricated of heavy gauge cold rolled steel panels. All exterior panels shall be insulated with 1/2″ thick, 3.35 pound per cubic foot, dual density fiberglass insulation rated for a maximum air velocity of 3600 f.p.m. Insulation shall conform to UL 181 for erosion and NFPA 90A and 90B for flame spread (25) and smoke developed (50) rating per ASTM E-84 and UL 723 and CAN/ULC, S102-M88.

Available Options:

- Provide a 16 gauge front panel on exposed units. Slope Top and recessed units shall include a recessed stamped louver discharge grille.

- Provide an architectural grade single deflection discharge grille with a powder coated paint finish to match cabinet color.

- Provide an architectural grade bar discharge grille with a powder coated paint finish to match cabinet color.

- Provide foil faced insulation in lieu of standard. Foil faced insulation shall meet or exceed the requirements stated above, and in addition, meet ASTM Standards C-665 and C-1136 for biological growth in insulation. Insulation shall be lined with aluminum foil, fiberglass scrim reinforcement, and 30 pound kraft paper laminated together with a flame resistant adhesive. All exposed edges shall be sealed to prevent any fibers from reaching the air stream.

- Provide elastomeric Elastomeric foam insulation in lieu of standard. Insulation shall conform to UL 181 for erosion and NFPA 90A for fire, smoke and melting, and comply with a 25/50 Flame Spread and Smoke Developed Index per ASTM E-84 or UL 723. Additionally, insulation shall comply with antimicrobial performance rating of 0, no observed growth, per ASTM G-21. Polyethylene insulation is not acceptable. Unit mounting shall be to the wall through 1/2″ holes in four locations in the back of the unit.

OUTSIDE AIR DAMPER

Provide a manual or two position motorized out side air damper integral to the unit.

Available Options:

- Provide an aluminum outside air wall box with louvers and integral bug screen and weep holes for field installation as indicated in catalog.

FAN / DRAIN PANS ASSEMBLY

Unit fan shall be dynamically balanced, forward curved, DWDI centrifugal type constructed of heavy gauge galvanized steel for corrosion resistance. Motors shall be high efficiency, permanently lubricated sleeve bearing, permanent split-capacitor type with UL and C-UL listed automatic reset thermal overload protection and three separate horsepower taps. Single speed motors are not acceptable.

Condensate drain pans shall be single wall, heavy gauge galvanized steel for corrosion resistance, and extend under the entire coil section. Drain pans shall be of one-piece construction and be positively sloped for condensate removal.

The drain pan shall be externally insulated with a fire retardant, Elastomeric foam insulation. The insulation shall carry no more than a 25/50 Flame Spread and Smoke Developed Rating per ASTM E-84 and UL723 and fungi resistant per ASTM G21/C1338, bacteria resistant per ASTM G22 and mold growth per UL 181. The fan/drain pan assembly shall be removed and serviced through the front panel. The entire assembly shall be able to slide out of the unit easily.

Available Options:

- Provide a primary drain pan constructed entirely of heavy gauge type 304 stainless steel for superior corrosion resistance. Stainless steel drain pans shall be externally insulated and meet or exceed the requirements stated above.

- Devices used to energize and de-energize (switch) fan speeds must be totally silent. Mercury and/ or quiet relays and/or contactors are not acceptable.

COILS

All cooling and heating coils shall optimize rows and fins per inch to meet the specified capacity. Coils shall have seamless copper tubes and shall be mechanically expanded to provide an efficient, permanent bond between the tube and fin.

Fins shall have high efficiency aluminum surface optimized for heat transfer, air pressure drop and carryover.

All coils shall be tested at 350 PSIG air pressure under water, and rated for a maximum 300 PSIG working pressure at 180°F maximum water temperature. Heating coils shall be furnished in the reheat position as standard.

Direct expansion cooling coils shall include a distributor and nozzle.

Steam coils shall be standard single tube steam type suitable for temperatures above 35°F and 15 PSIG maximum working pressure.

All water coils shall be provided with a manual air vent fitting to allow for coil venting.

Available Options:

- Provide automatic air vents in lieu of manual-air vents.

ELECTRIC HEAT

Furnish an electric resistance heating assembly as an integral part of the fan coil unit, with the heating capacity, voltage and kilowatts scheduled. The heater assembly shall be rated for installation on the fan coil unit and be located so as not to expose the fan assembly to excessive leaving air temperatures that could affect motor performance.

The heater and unit assembly shall be listed for zero clearance and meet all NEC requirements, and be UL listed with the unit as an assembly and also in compliance with UL/ANSI Standard 1995.

All internal wiring shall be rated for 90°C minimum.

All heaters shall include over temperature protection consisting of an automatic reset primary thermal limit and replaceable back up secondary thermal limit. All heaters shall be single stage.

All units shall be provided with an incoming line power distribution block, designated to accept single point power wiring capable of carrying 125% of the calculated load current.

Available Options:

- Devices used to energize and de-energize (switch) electric heat must be totally silent. Mercury and/ or quiet relays and/or contactors are not acceptable.

PIPING PACKAGES

Provide a factory assembled valve piping package to consist of a 2 or 3 way, on/off, motorized electric control valve and two ball isolation valves. Control valves shall be piped normally closed to the coil. Maximum entering water temperature on the control valve shall be 200°F, and maximum operating pressure shall be 300 PSIG.

Available Options:

- Provide 3-wire floating point modulating control valve (fail in place) in lieu of standard 2 position control valve with factory assembled valve piping package.

- Provide high pressure close off actuator for 2 way on/off control valve. Maximum close off pressure is 75 PSIG (1/2″) or 50 PSIG (3/4)”. Piping packages are shipped installed on all units and can be shipped separately by request only.

FILTERS

All units shall be furnished with a minimum 1″ nominal glass fiber throwaway filter. Filters shall be tight fitting to prevent air bypass. Filters shall be easily removable from the return-air opening without the need for tools or removal of the front panel.

Available Options:

- Provide unit with 1″ pleated filter (MERV 6).

- Provide a decorative stamped louver grille in the return air opening.